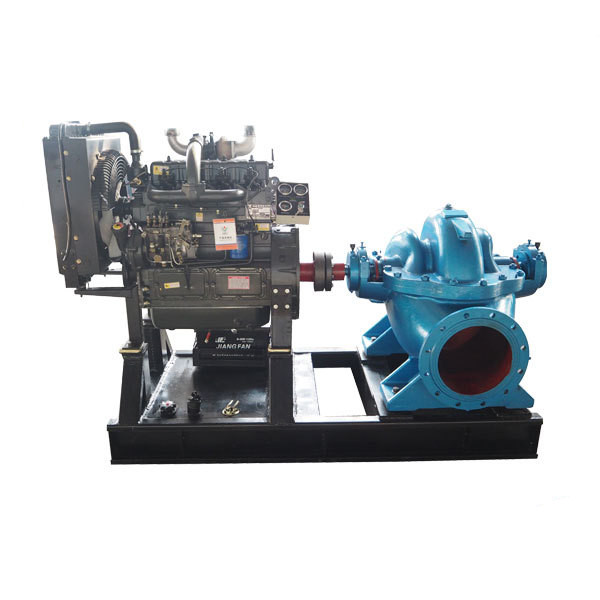

The diesel driven pump is composed of a diesel engine and a fire pump. The pump unit is a horizontal, single-suction, multi-stage centrifugal fire pump. It has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long life, and convenient installation and maintenance. For transporting clean water or other liquids with physical and chemical properties similar to water. It can also be used to transport hot water, oil, corrosive or abrasive media by changing the material and sealing form of the pump's flow-through components and adding a cooling system.

1. The correct maintenance of diesel driven pump, especially preventive maintenance, is the easiest and most economical maintenance, so it is the key to extending the service life and reducing the cost of use. Routine maintenance can be carried out according to the following steps to check the fuel quantity of the fuel tank—observe the fuel storage quantity of the fuel tank and refill it as needed.

2. Check the oil level in the oil pan: observe whether the oil level reaches the mark on the oil gauge. If it is insufficient, add the specified amount, but not exceed the upper limit of the scale.

3. Check the oil level of the fuel injection pump governor: If the diesel driven pump does not reach the specified engraved mark, add enough oil (some fuel injection pump governors do not have a scale, so this step can be omitted).

4. Check whether there is sufficient lubricating grease in the oil filling point of the water pump: Remove the grease nipple on the circulating water pump of the diesel engine and observe whether the lubricating grease inside is sufficient. If insufficient, use a grease gun to inject sufficient grease into the inside.

5. Check whether the water in the water tank is sufficient: If the water in the water tank is found to be insufficient, it should be replenished in time. The added water should be clean fresh water, such as tap water or clean river water. If the groundwater is used directly, it is easy to form scale in the water tank, which will affect the cooling effect and cause malfunction. Therefore, the groundwater can be used after softening. In the north (the ambient temperature is below zero), an antifreeze with an appropriate freezing point must be configured according to the local minimum temperature.

6. Check the fuel injection pump drive connection plate: check whether the connection screw is loose. If it is loose, re-correct the fuel injection advance angle and tighten the connection screw.

7. Clean the exterior of the diesel engine and ancillary equipment: wipe off the oil, water and dust on the surface of the fuselage, turbocharger, cylinder head cover, air filter, etc. with a dry cloth or a rag soaked in diesel; wipe or use The compressed air blows away the dust on the surface of the charging generator, radiator, fan, etc.

The biggest difference between diesel driven pump and electric water pump is that it has its own independent power supply system-battery. Therefore, the start and operation of diesel driven pump can be completely separated from the mains.

diesel driven pump is usually used as a backup facility. Therefore, it will only start automatically when the fire signal comes, and the electric water pump fails or the power supply is cut off. When a diesel driven pump has an ultra-low pressure pump start device, its matching electric water pump control cabinet should also have an ultra low pressure pump start device, and the lower limit of the two pumps should have a certain pressure difference. Of course, we can also design a control system that is more suitable for customer needs according to customer requirements.