Installation and precautions

1. Before installation, carefully check whether there are hard objects in the flow passage of the pump body to avoid damage to the impeller and pump body during operation.

2. A regulating valve should be installed on the inlet and small port 1 pipelines of the pump to control the pump to run under rated conditions.

3. Open the inlet valve to fill the entire pump cavity with liquid.

4. Turn on the power, when the pump reaches the normal speed, gradually open the valve on the spitting pipeline and adjust to the required working condition.

5. Check that the temperature rise at the motor and bearing is less than or equal to 70℃, and deal with the abnormality in time.

6. It is strictly forbidden for mechanical seals to work under dry grinding conditions.

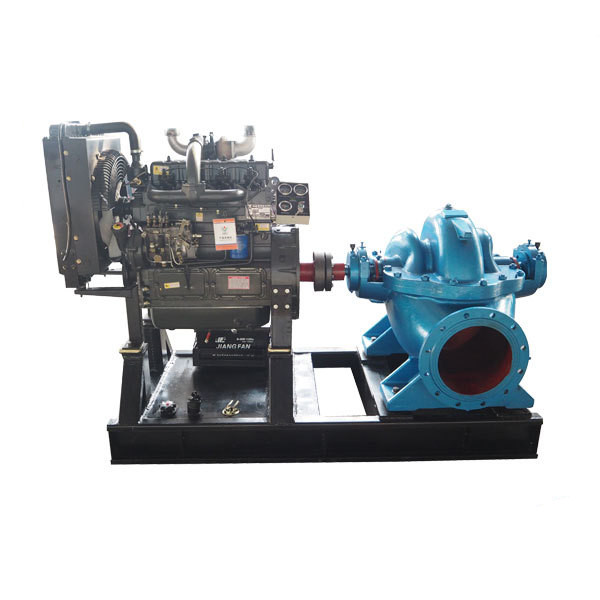

Diesel driven pump adopts domestic hydraulic model, adopts the performance parameters of IS-type centrifugal pump and ISW-type pipeline pump, and is designed by ingenious combination on the basis of general horizontal pipeline pump. The shaft seal of this product adopts cemented carbide mechanical seal device. This series of products have the advantages of high efficiency, energy saving, low noise and reliable performance. It meets the JB/T53058-93 standard requirements of the Ministry of Machinery, and is designed and manufactured according to the international ISO2858 standard. It is used to transport clear water or other liquids with physical and chemical properties similar to water, and the temperature is not higher than 80℃.

When diesel driven pump works, it relies on the high-speed rotating impeller, and the liquid gains energy under the action of inertial centrifugal force to increase the pressure. Before the centrifugal pump works, the pump body and the inlet pipeline must be filled with liquid medium to prevent cavitation. When the impeller rotates rapidly, the blades prompt the medium to rotate quickly, and the rotating medium flies out of the impeller under the action of centrifugal force. After the water in the pump is thrown out, the central part of the impeller forms a vacuum area. While continuously inhaling liquid, while continuously giving a certain amount of energy to the inhaled liquid and expelling the liquid, it works continuously.

With a wide range of head and flow, it can fully meet the fire-fighting water supply of warehouses, docks, airports, petrochemicals, power plants, liquefied gas stations, textiles and other industrial and mining enterprises. The advantage is that the electric fire pump cannot be started after the power system of the building is suddenly cut off, and the diesel fire pump is automatically started and put into emergency water supply.

Diesel driven pump is composed of a diesel engine and a fire pump. The pump unit is a horizontal, double-suction, single-stage centrifugal fire pump. It has the characteristics of high efficiency, wide performance range, safe and stable operation, low noise, long life, convenient installation and maintenance. It is used to transport clean water or other liquids with physical and chemical properties similar to water. It can also be used to transport hot water, oil, corrosive or abrasive media by changing the material of the pump's flow parts, sealing form and adding a cooling system.