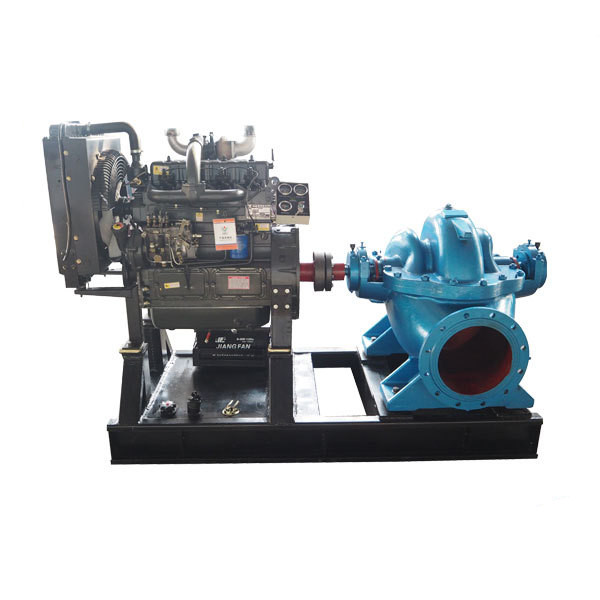

Diesel driven pump introduces the basic principles of frequency conversion speed regulation. According to the small square method, the performance curves of different parallel configuration schemes of pumps are derived theoretically, and the corresponding performance curves are drawn using MATLAB engineering software. Then, it discusses the energy-saving principle of variable-frequency speed regulation in different water pump configuration schemes, analyzes its energy-saving effect theoretically, and calculates the speed regulation range of water pump variable-frequency speed regulation by using graphic method. After that, a typical project was selected for diesel engine pumps. First, through calculation and analysis, the energy-saving effects of variable frequency speed regulation were compared with different parallel configuration schemes of water pumps. Then, the speed adjustment range of the water pump in the system is calculated.

The design concept of an automatic control system for a coal mine main drainage pump. The application automatically controls the water pump to realize the functions of water level monitoring, automatic start and stop of the water pump, and fault self-diagnosis. And can communicate with the host computer, realize remote control and online monitoring, and improve the automation level and safety of coal mine. The development status and trends of water pumps at home and abroad are introduced, and the gap between the energy consumption level of my country's water pump industry and the country, and the challenges faced by water pump energy saving are analyzed. Through the case analysis of energy-saving renovation of circulating water pumps in thermal power plants, the technical approaches and energy-saving effects of water pumps in my country are proposed. , And measures to further improve energy efficiency in my country's water pump industry.

The full characteristic curve of diesel driven pump shows "S" characteristics in the pump working condition and backwater pump area, and the curves have cross and overlap phenomena. This multi-valued flow and torque will bring inconvenience to the transition process analysis. The improved Suter curve transformation method converts the full characteristic curve of the diesel engine pump in the four quadrants into two groups of cyclically changing curves, namely the WH (x, y) line and WM (x, y) line; while maintaining the original data On the basis of the constant curve characteristics, the full characteristic curve of the diesel engine pump is transformed, and then the small square surface fitting mathematical model is used to perform surface fitting on the transformed WH curve and WM curve, and 2 sets of curves are obtained. The three-dimensional surface fitting graph. The transformed WH curve and WM curve are smooth and smooth, becoming two sets of approximately parallel curves, which eliminates the uneven distribution of the Suter conversion curve and the variability of interpolation.

This eliminates the cross and overlap phenomenon of the diesel driven pump full characteristic curve in the water pump and backwater pump area and the uneven distribution of the two ends of the curve, which provides convenience for the analysis of the transition process of diesel engine pumps. Water pump testing technology for the research and basic theory of water pumps Development, improvement of pump performance, and perfection of pump design methods all play an extremely important role. Therefore, the research of automatic test system for comprehensive parameters of pumps has become one of the topics of widespread concern in the industry. At present, domestic water pump testing systems have low measurement accuracy, poor real-time performance and poor reliability. Many of them are traditional semi-automatic forms, with scattered position measurement, no integrated management of all measurement signals, and human-machine interface is not friendly enough. Compared with foreign countries, the level of technology is relatively backward.