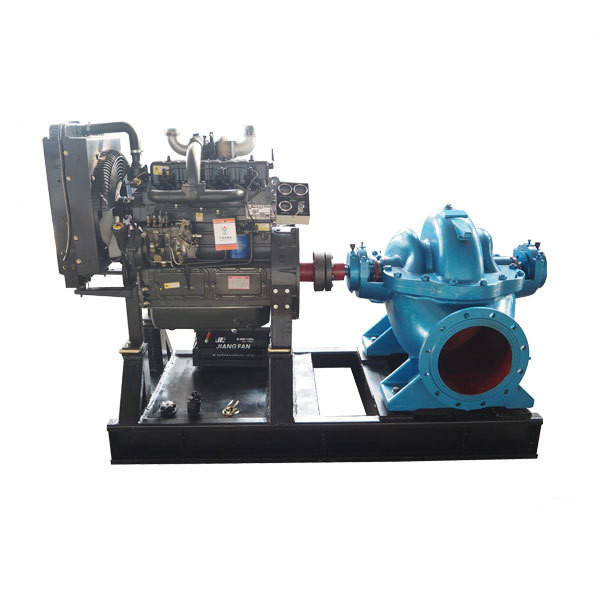

Today I will introduce to you what are the requirements for the installation of diesel driven pump?

1. If the water pump has any minor faults, remember not to let it work. If the filler of the water pump shaft is completely worn out, it should be added in time. If the pump continues to be used, air leakage will occur. The direct effect of this is that the energy consumption of the motor will increase, which will damage the impeller.

2. If there is a strong vibration during use, you must stop and check the cause, otherwise the pump will also be damaged.

3. When the bottom valve of the pump leaks, some people will fill the inlet pipe of the pump with dry soil and flush the bottom valve with water. This is really undesirable. Because when the dry soil is put into the water inlet pipe, the dry soil will enter the pump when the pump starts to work, which will damage the impeller and bearings of the pump, which shortens the pump. When the bottom valve leaks, it must be repaired. If it is serious, it needs to be replaced.

4. After using the pump, you must pay attention to maintenance. For example, when the pump is used up, the water in the pump should be drained, so that the pipe can be unloaded

5. The tape on the water pump should also be removed, and then rinse it with water and dry it in a light place. Do not put the tape in a dark and humid place. The tape of the water pump must not be stained with oil, and do not apply something sticky to the tape.

6. Check carefully whether there are cracks on the impeller and whether the impeller is fixed on the bearing for looseness. If there are cracks and looseness, repair it in time. If there is mud on the pump impeller, clean it up.

7. The interface between the diesel driven pump and the pipeline must be well sealed, because if debris enters, it will damage the inside of the pump.

8. The bearing on the pump is also the focus of inspection. After use, check whether the bearing is worn or not. If the water pump is used for a long time, the small balls in the bearing will break, so when the water pump is used, it is better to apply a layer of lubrication to the bearing Oil better protects the water pump bearings.