To ensure the reliability of the entire control system of diesel driven pump, perfect daily management is inseparable. Although the diesel engine fire pump has a high degree of automation, it often happens that the man-made destructive factors cause it to lose its function. The components are damaged or lost, the parameters of the time relay and the charger are incorrectly modified, etc. Therefore, the key of the pump room must have a dedicated person Management, and regularly check whether equipment parts are lost or damaged by other factors, and whether the parameters of each component are scientific and reasonable.

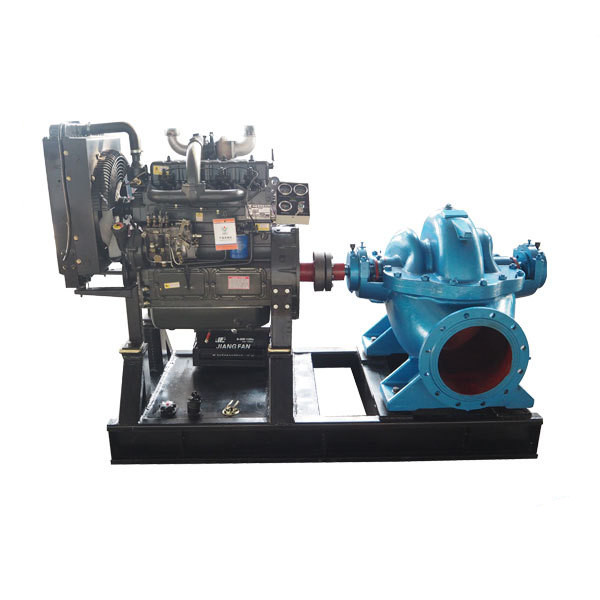

After receiving the fire alarm/pipeline pressure/power outage/or other start signals, the diesel driven pump can automatically start and put into full-load operation within 15 seconds. The battery can be automatically charged by the mains or diesel charging motor to ensure the smooth start of the unit. Automatic alarm protection for diesel engine low oil pressure, high water temperature and other faults, alarm and shutdown when overspeed, so that the diesel engine is in a warm standby state to ensure emergency work. The diesel engine fire pump adopts domestic diesel engine and water pump direct connection technology through elastic coupling, which reduces the point of failure, greatly shortens the start-up time of the unit, and increases the reliability and emergency performance of the unit.

Diesel driven pump is suitable for mobile sewage discharge places. The product has the characteristics of high automation, superior performance, complete protection functions, reasonable structure, easy installation, and high cost performance. Regularly check the current value of the motor. When the ambient temperature is the rated temperature of the motor, the current must not be When the rated current of the motor is exceeded, and the ambient temperature is lower than the rated temperature of the motor, the current can be appropriately increased. For the specific increase value, please refer to relevant information. When the current is abnormal, the cause should be found out. Check the oil quality in the oil chamber of the diesel engine fire pump regularly. If the oil is found to be emulsified, replace the N10 or N15 mechanical oil. After the diesel engine fire pump has been running for a long time, if the noise and vibration of the unit increase due to mechanical wear, the machine should be stopped and inspected. If necessary, the vulnerable parts or bearings and mechanical seals can be replaced. The overhaul period of the unit is generally one year. The cumulative life of the mechanical seal under normal use conditions is more than 8000 hours. The use and maintenance of the diesel engine fire pump should be carried out in accordance with the instruction manual.

Diesel driven pump is an excellent multi-purpose pump with complete functions, high degree of automation, compact structure, automatic fault alarm and receiving start signal, complete the start procedure by itself, and can quickly put into full load operation. In order to ensure the fresh air in the engine room, avoid a large amount of heat radiating indoors, and reduce noise, the exhaust pipe of the diesel engine fire pump should be wrapped with asbestos and connected to the outdoors with rainproof device or 30° downward installation and a muffler. Exhaust pipe bends should be as few as possible, and the bending radius of the bend should be greater than 2.5 times the outer diameter of the exhaust pipe. The support of the exhaust pipe should be considered to reduce vibration and avoid factors such as adding its weight to the diesel engine. There should be a passage and space of about 1m on both sides of the diesel engine fire pump and in front of the cooling fan and the water tank to facilitate better heat dissipation, equipment repair and maintenance. The height of the machine room should be determined according to the height of the equipment and the lifting equipment. Generally, the effective height is 3~5m.